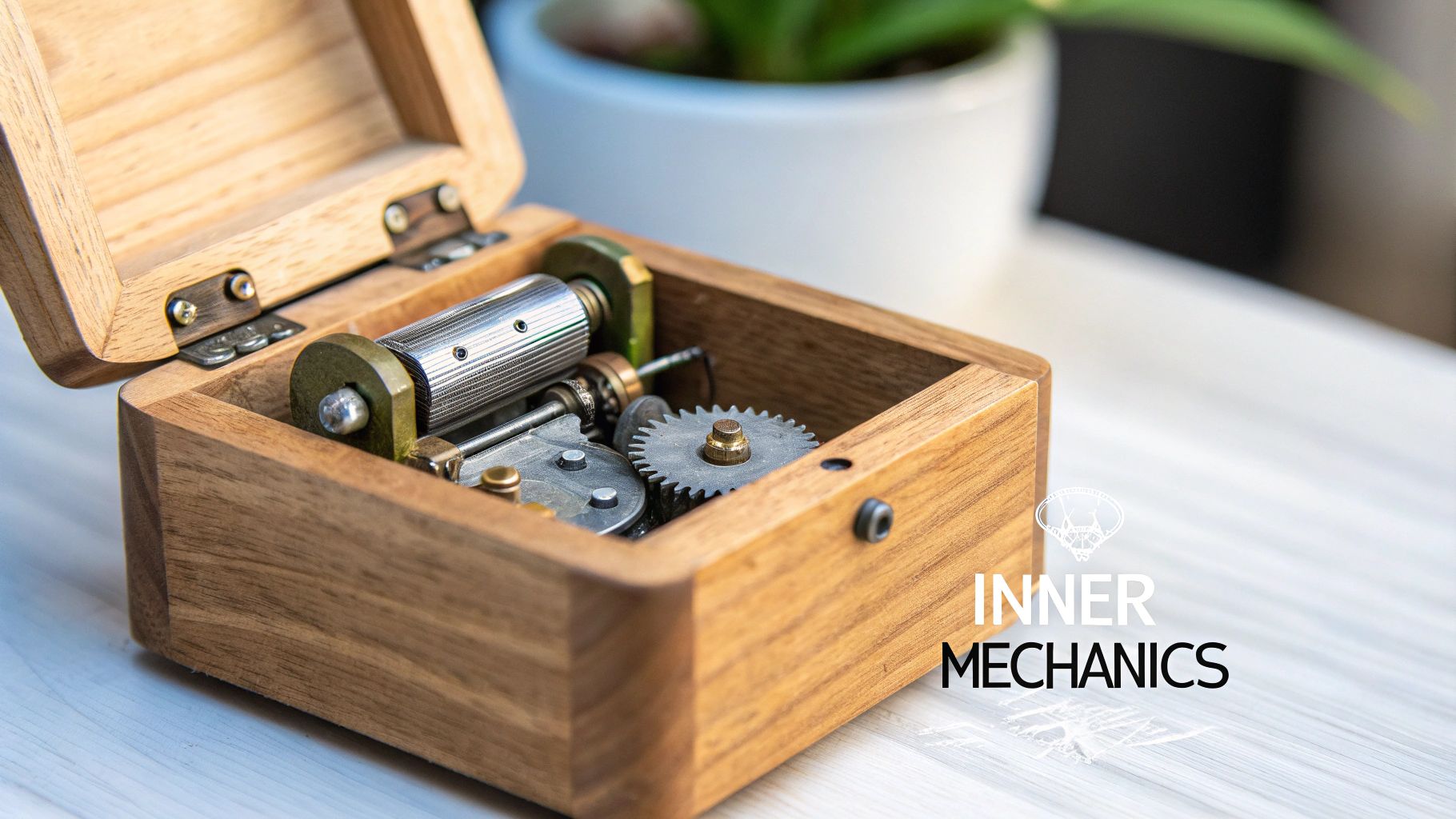

At its most basic, you can think of a music box as a tiny, automated harp. A rotating cylinder studded with pins plucks the tuned teeth of a steel comb, and just like that, you have a melody. It’s a beautifully simple mechanical process that needs no batteries or electricity, running entirely on the energy you provide with a wind-up key.

The Hidden Mechanics of a Music Box

That enchanting sound might seem like magic, but it's actually the result of some brilliant, old-school mechanical engineering. Every single component has a job to do, working together in perfect harmony to turn a simple wind-up motion into a recognizable tune. To really get how a music box works, we need to pop the hood and look at the four essential parts that make the music happen.

These pieces are the engine, the transmission, and the orchestra all in one. The whole system is a fantastic little display of physics in action, where the potential energy you store by winding it up is converted into kinetic energy and, finally, into the sound waves that create the song.

The Core Components Explained

Imagine the inside of the box as a miniature factory built for one purpose: producing a single song. Each part has a very specific role, and if one piece falters, the whole performance grinds to a halt. It’s the intricate dance between these components that turns a few cranks of a key into a captivating melody.

Let's take a quick look at the main players inside a music box and what they do.

Key Components Inside a Music Box

| Component | Primary Function |

|---|---|

| Mainspring | The power source; a coiled spring that stores energy when wound. |

| Gear Train | The transmission; controls the release of energy from the mainspring. |

| Cylinder/Disc | The sheet music; contains the "notes" in the form of tiny pins. |

| Comb | The instrument; its tuned teeth are plucked by the pins to produce sound. |

Essentially, these are the four pillars that support the entire musical performance. Now, let's break down what each one actually does.

- The Mainspring: This is the powerhouse. When you turn the winding key, you're coiling this flat spring tighter and tighter, storing potential energy. It’s the same principle as stretching a rubber band.

- The Gear Train: Think of this as the transmission. It takes the raw, powerful energy from the unwinding mainspring and slows it down, translating it into a smooth, controlled rotation for the cylinder.

- The Cylinder (or Disc): This is the "sheet music" for the device. Tiny pins are meticulously placed across its surface, with each pin's location corresponding to a specific note in the song.

- The Comb: This is the instrument itself. It’s a flat piece of steel with a series of tuned "teeth" or tines of varying lengths. As the cylinder turns, the pins catch and pluck these teeth, causing them to vibrate and create the distinct musical notes you hear.

The real magic of a music box is in its elegant simplicity. It’s a completely self-contained system that uses nothing but stored mechanical energy and the physical contact between a few core parts to create something so beautiful and complex.

This clever combination of parts—from the pent-up energy in the mainspring to the final vibration of a single tooth on the comb—is the complete story of how a music box works. Next, we’ll dive deeper into each of these components to appreciate the incredible precision and craftsmanship that bring these mechanical wonders to life.

The Soul of the Sound: The Comb and Cylinder

If the mainspring is the engine of a music box, then the comb and cylinder are its heart and voice. This is where all that mechanical energy finally becomes music. The elegant dance between these two parts is what turns a series of simple physical plucks into a tune you can recognize.

Think of it like a miniature piano player. The cylinder is the musician reading the score, and the steel comb is the piano itself, ready to play.

The Comb: The Music Box Orchestra

The tuned steel comb is where the sound actually comes from. It’s a flat piece of metal with a row of teeth, also called tines, cut into it. Each individual tine is carefully crafted to produce one specific musical note when it vibrates.

It really is like a tiny harp or the inside of a piano. The length of each tooth determines its pitch, just like the strings on a larger instrument.

- Longer Tines: Create the low, deep notes.

- Shorter Tines: Produce the high, delicate notes.

Making a comb is a true art form. Every tooth has to be cut and then painstakingly filed down to hit the perfect pitch. A tiny error can make a note sharp or flat, throwing the whole melody out of tune. On the best antique music boxes, this was all done by hand, a real testament to the craftsman's skill.

The material of the comb is also essential. Most are made from high-carbon tempered steel, which is chosen for its ability to produce a bright, clear, and sustained tone. It's this choice of material that gives music boxes their signature bell-like chime.

The number of teeth on the comb dictates how complex the music can be. A simple, modern music box might only have 18 notes. In contrast, a grand antique orchestral model could have over 100 notes, allowing it to play rich harmonies and incredibly detailed arrangements.

The Cylinder: A Musical Score in Metal

While the comb is the instrument, the pinned cylinder is the sheet music. This rotating brass drum is covered in hundreds—or even thousands—of tiny steel pins. These pins aren't just placed randomly; they are a physical map of a song.

Each pin's location is plotted with mathematical precision to control two things:

- Which note to play: Its position along the cylinder’s length lines it up with a specific tooth on the comb.

- When to play it: Its placement around the cylinder’s curve determines the exact timing of the note.

As the cylinder turns, its pins catch the tips of the comb’s tines. A pin lifts a tine up and then lets it go, causing it to vibrate and create its note. This perfectly timed sequence of plucks is what forms the melody.

This mechanism was one of the earliest forms of mass-produced entertainment. When you listen to an antique box, you're hearing a marvel of 19th-century engineering. The core concept—a pinned brass cylinder plucking a tuned steel comb—was patented by Swiss watchmaker Antoine Favre way back in 1811. By the 1870s, this design fueled an industry that produced over 2 million music boxes a year in Germany and Switzerland, with most vintage models featuring between 18 and 72 notes. You can find more about the history of these amazing devices and their inventors at Only One Music Box.

Powering the Performance: The Winding Mechanism and Governor

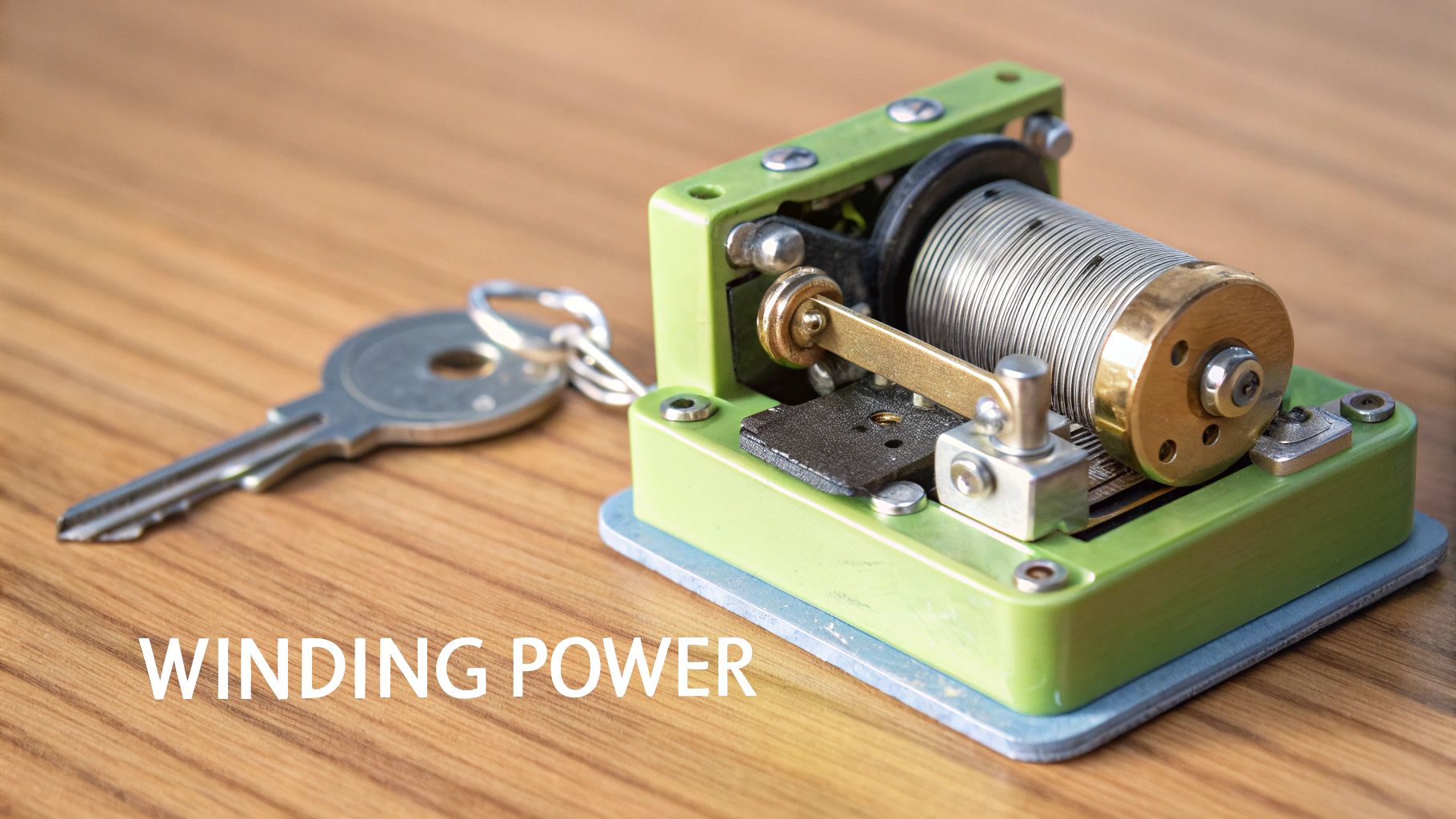

While the comb and cylinder are the stars of the show, creating the actual music, none of it would happen without the winding mechanism. It’s the clockwork motor, a tiny, efficient engine that powers the whole performance without a single battery. At its heart are two essential components: the mainspring, which stores all the power, and the governor, which makes sure the music plays at a perfect, steady pace.

You can think of this system as the music box's power plant and its conductor. One provides the raw energy, and the other tames it. Grasping how this little engine works is key to understanding the magic of a music box.

The Mainspring and Gear Train

It all starts when you turn the winding key. Every twist coils a long, flat strip of metal—the mainspring—into a tight spiral inside its housing. Picture a coiled snake, just waiting to release its stored energy. That's your mainspring.

Let go of the key, and the spring naturally starts to unwind. But if all that energy were released at once, the cylinder would spin wildly, and the melody would just be a high-speed garbled mess. That's where the gear train steps in.

This series of interlocking gears acts like a car's transmission. It takes the powerful, slow unwinding of the mainspring and translates it into the controlled rotation needed to turn the pinned cylinder at just the right speed. It’s an elegant transfer of energy that keeps the music moving forward.

The entire operation is a beautiful display of physics. The potential energy you create by winding the key is methodically converted into the kinetic energy of the moving parts, all managed by the ingenious clockwork mechanism.

The Governor: The Unsung Conductor

Now for the secret ingredient: the governor. This small, rapidly spinning part is the unsung hero that guarantees a music box's steady, pleasant tempo. Without it, the music would race at the beginning and then crawl to a stop as the mainspring lost tension.

Often looking like a tiny propeller or a pair of small weights on arms, the governor (also known as a centrifugal or air brake) spins incredibly fast along with the gear train. This high-speed rotation creates air resistance—drag—which acts as a natural brake on the whole system. The faster it tries to spin, the more air resistance it runs into, forcing it to slow down.

This simple but brilliant device ensures the mechanism maintains a constant speed, from the first note to the last. It’s why the melody doesn’t sound frantic when fully wound and sluggish as it runs down. Just like the delicate regulator in an antique clock, the governor is an absolute master of keeping time.

Comparing Cylinder and Disc Music Boxes

For decades, the classic pinned cylinder was the heart and soul of the music box. But as the 19th century drew to a close, a new challenger appeared on the scene—one that would completely change the game for mechanical music and spark a fierce rivalry between two brilliant technologies. This was the dawn of the disc music box.

The basic idea was still the same: pluck the teeth of a tuned steel comb to make a melody. The big difference? Instead of a fixed cylinder with a handful of songs, this new design used large, interchangeable metal discs. It was a leap forward not unlike the jump from a single album to a library of vinyl records, and it marked the single greatest evolution in how a music box works.

The Rise of the Disc Player

Disc music boxes work with a slightly different, though equally clever, mechanical setup. Rather than having pins on a cylinder pluck the comb directly, the disc system uses an indirect method that generates a much more powerful and resonant sound. It was built from the ground up for volume and variety.

Here’s a look under the hood:

- The Metal Disc: Think of this as the sheet music. It's a flat, perforated metal circle with tiny bumps, or "projections," stamped onto its underside. Each projection represents a musical note.

- The Star Wheels: Sitting just beneath the disc is a row of small, star-shaped wheels. As the disc turns, those little projections catch the points of the star wheels, forcing them to spin.

- The Comb: Each star wheel is mechanically linked to a specific tooth on the steel comb. When a star wheel gets a "kick" from a disc projection, it plucks its matching tooth with surprising force, producing a loud, clear note.

This indirect plucking mechanism was a game-changer. The star wheels acted like tiny levers, striking the comb's teeth much harder than the delicate pins of a cylinder ever could. The result was a loud, rich, and brilliant sound that could easily fill a large parlor room.

First appearing around 1885, the disc mechanism completely shook up the music box world. Invented by the German firm Polyphon, it offered a library of swappable tunes that dramatically expanded what a single box could do. The perforated metal discs—often 10-20 inches in diameter on larger models—spun on a central spindle.

This new technology took off like a rocket. By 1900, factories were churning out over 100,000 disc boxes a year, and they had captured 60% of the US market—a business valued at $5 million annually back then.

Key Differences in Design and Experience

The split between cylinder and disc models created two very different experiences for listeners, each with pros and cons that collectors still weigh today. Knowing these differences is key to identifying and valuing an antique piece.

The choice between a cylinder and a disc music box in the late 1800s was like choosing between a single, beautifully bound book and an entire library. One offered depth and craftsmanship in a single piece, while the other offered an ever-expanding world of new stories.

This table gives you an in-depth look at the key differences between the two primary types of antique music box mechanisms. It really highlights how each design catered to a different kind of music lover.

Cylinder Music Boxes vs Disc Music Boxes

| Feature | Cylinder Music Box | Disc Music Box |

|---|---|---|

| Music Format | A fixed set of tunes on a pinned brass cylinder. | Interchangeable perforated metal discs. |

| Sound Quality | Often more delicate and intricate, with a softer tone. | Louder, brighter, and more resonant. |

| Tune Library | Limited to the songs pinned on its single cylinder. | Potentially limitless; new discs could be purchased. |

| Cost | High-end models were very expensive due to precision. | Generally more affordable for consumers to start a collection. |

| Collectibility | Valued for intricate craftsmanship and Swiss origins. | Valued for variety, size, and makers like Regina or Polyphon. |

Ultimately, this innovation really paved the way for the home entertainment industry, setting a precedent for later technologies. You can see how this concept of interchangeable media evolved in our guide on the gramophone vs the phonograph. Both cylinder and disc music boxes are incredible feats of engineering, each telling a unique and fascinating chapter in the story of mechanical music.

A Brief History of Mechanical Music

To really get how a music box works, you have to look past the gears and pins and see its place in a fascinating story of invention. This journey doesn’t start in a concert hall, but on the benches of master craftsmen in 18th-century Switzerland. These were the watchmakers, the undisputed experts in tiny, intricate mechanics, and they were the first to build miniature musical movements.

In the beginning, these weren't the standalone boxes we think of today. They were delightful little novelties tucked inside objects for the wealthy—think snuff boxes, pendants, and watches. One of the earliest pioneers was Antoine Favre-Salomon, a Geneva watchmaker who, in 1796, ingeniously integrated a pinned cylinder and tuned steel teeth into a watch. That single invention became the blueprint for every music box that followed.

The Golden Age of the Music Box

The 19th century was, without a doubt, the golden age for the music box. As manufacturing got better and more refined, these delicate little contraptions grew from pocket-sized curiosities into impressive parlor instruments. Swiss towns like Geneva and Sainte-Croix became the world's music box capitals, setting the standard for quality and artistry.

For most of the Victorian era, the music box was the only way to have music on demand at home. It was the original home stereo, filling living rooms with popular opera tunes, waltzes, and hymns long before the phonograph was even a dream. Owning a large, ornate box—especially one with multiple cylinders, bells, or drum effects—was a true symbol of taste and social standing.

The rise of the music box was a huge cultural shift. For the first time, families could enjoy beautiful musical performances in their own homes without hiring musicians. It created shared experiences that were previously out of reach for most people.

This booming industry was constantly pushing forward. Craftsmen kept experimenting with bigger cylinders and more complicated musical arrangements, stretching the limits of what these mechanical wonders could do. The period from roughly 1810 to 1890 truly represents the peak of the cylinder music box, both in its popularity and its technical sophistication.

The Dawn of a New Era

But the music box’s reign as the king of home entertainment couldn't last forever. In 1877, Thomas Edison invented the phonograph, and this new technology was a challenger the music box industry simply couldn't beat. Recorded sound offered a richness and variety that even the most elaborate mechanical instrument couldn’t match.

It’s fascinating to see how sound reproduction has evolved over the centuries. The idea of mechanical sound continues today, just in different forms. If you look at unique gifts for vinyl collectors, you can see that same appreciation for physical, tangible music playback.

By the early 20th century, the phonograph and the radio had won the public over. The once-thriving factories in Switzerland and Germany either shut their doors or shifted their focus to other precision goods, like watches or gramophones. The music box was no longer the main way people listened to music, but its legacy as a masterpiece of mechanical art and a pioneer of home entertainment was already set in stone.

How to Care for an Antique Music Box

When you own an antique music box, you’re not just an owner—you’re a custodian of history. These delicate mechanical marvels have survived for a century or more, and with the right care, they can keep enchanting for generations. The good news is that preservation is less about complex repairs and more about gentle, consistent maintenance.

Proper care is everything. It directly impacts your music box's performance and its value. A well-maintained piece doesn't just play its melody with crisp clarity; it holds its worth as a cherished collectible. A little knowledge goes a long way in protecting your heirloom from the common pitfalls that can degrade its mechanism over time.

Gentle Winding and Handling

The most common way you'll interact with your music box is by winding it, and that’s a moment to be careful. Here's the golden rule: never over-wind the mainspring. Turn the key slowly until you feel the tension build. Don't force it past that point. Pushing it further can strain or even snap the spring, which means a trip to a specialist and a costly repair.

Always handle the box with two hands from the base, not by the lid or delicate edges. The old hinges can be fragile. When the lid is open, resist the urge to touch the inner workings like the pinned cylinder or the steel comb. The oils from your fingers are surprisingly corrosive and can gum up the very parts that make the music.

Creating the Ideal Environment

Believe it or not, where you keep your music box is just as important as how you handle it. The blend of wood and metal makes it incredibly sensitive to its surroundings. Consistency is your best friend here.

Here’s what to aim for:

- Stable Temperature: Keep it away from radiators, fireplaces, and direct sunlight. Heat can dry out and crack the wooden case, and big temperature swings create condensation—the mortal enemy of metal parts.

- Controlled Humidity: The sweet spot is a humidity level between 45% and 60%. Too damp, and you risk rust and swollen wood. Too dry, and the case can warp and split.

- Clean and Dust-Free: Keep the lid closed when you’re not playing it. Dust acts like fine sandpaper on the moving parts, causing unnecessary wear and tear over the years.

For the outside, a gentle wipe with a soft, dry cloth is usually all you need. If the case needs a bit more love, be sure you know how to clean antique wood properly to avoid causing accidental damage.

Knowing When to Call a Professional

Knowing your limits is critical. While regular dusting and careful handling are things you can do, attempting a DIY repair on a complex antique mechanism almost always ends badly and can tank its value.

A music box's value is intrinsically tied to the condition of its mechanism. A broken comb tooth or a stripped cylinder pin isn't just a minor flaw—it's a significant blow to the piece's historical integrity and market worth.

The tuned steel comb is the heart of the machine. Pristine teeth can boost a box’s value by up to 40%, while stripped pins can drop it by 25%. The incredible precision of these components is what made music boxes the pinnacle of home entertainment before the phonograph came along.

It’s time to find a professional restorer if you notice any of these red flags:

- Broken or Bent Comb Teeth: This is the most serious problem. Fixing it requires specialized tools and a steady hand to avoid ruining the entire comb.

- A Jammed or Sluggish Mechanism: If the music drags, plays too slowly, or just stops, the old lubricants have likely turned to sludge. The movement needs a professional cleaning and re-oiling.

- Grinding or Clicking Noises: Strange sounds often point to a misaligned gear or a bent pin on the cylinder—not something you want to try prying at yourself.

Common Questions About Music Boxes

Even after you get the hang of how a music box works, a few questions always seem to pop up. Whether you're a new owner or have been collecting for years, here are some answers to the most common queries I hear.

Why Does My Music Box Play the Same Short Tune Over and Over?

This is probably the most frequent question I get. The simple answer is that most cylinder music boxes are built to play just one short musical phrase—whatever fits on a single rotation of the cylinder. Think of the cylinder's surface as a single, looping page of sheet music. It can only hold so many pins, so the tune is naturally short.

Of course, the more sophisticated (and valuable) antique models found a way around this. You'll find some with massive cylinders that hold more music, or even clever designs where the cylinder actually shifts slightly to the side to play a whole new set of pins on a different track.

Can a Music Box Comb with a Broken Tooth Be Repaired?

Yes, it can, but this is a job that absolutely requires a specialist. Fixing a broken tine on that steel comb is incredibly delicate work. A professional restorer has to carefully braze a new piece of perfectly tuned steel in its place or, in some cases, replace the entire tooth from the base.

This is not a DIY project. A botched repair can easily throw the entire comb out of tune, damage the teeth next to it, and completely tank the music box's historical and monetary value. Please, always find an expert for comb repairs.

How Can I Tell How Old My Music Box Is?

Dating an antique music box is a bit like playing detective; you have to look for the clues. Start by searching for a manufacturer's name, a serial number, or any kind of maker's mark. These are often stamped on the mechanism itself, hidden somewhere on the wooden case, or printed on the tune sheet glued inside the lid.

If that doesn't give you a clear answer, the style of the box is your next best clue. The type of wood used, how intricate the inlay is, and the overall design can tell you a lot about the era it came from. The mechanism itself also holds secrets:

- Cylinder vs. Disc: Cylinder boxes are generally the older style. The big shift to disc players happened after 1885.

- Number of Notes: The number of teeth on the comb is often a good indicator of its quality and, by extension, its age. More teeth usually meant a higher-end, more complex piece.

For a really accurate date, consulting a professional appraiser or using a specialized identification app is the best way to uncover its full history.

Have an old music box or another heirloom you're curious about? Let Curio do the detective work for you. Just snap a photo to instantly identify your item, learn its history, and get an estimated value. Download Curio today at https://www.curio.app and uncover the stories hiding in your home.